How is a Paper Cup Manufactured for Bulk Procurement?

The paper cup manufacturing process combines art, science, and technology. By understanding the process, you can better appreciate how these ubiquitous products are made.

Choosing the right materials is crucial in the paper cup manufacturing process. You need food-grade paperboard sourced from sustainably managed forests. This step ensures a product that meets safety and environmental standards. Additionally, the paperboard undergoes cleaning, pulping, and bleaching. These steps remove impurities and create a desirable whiteness.

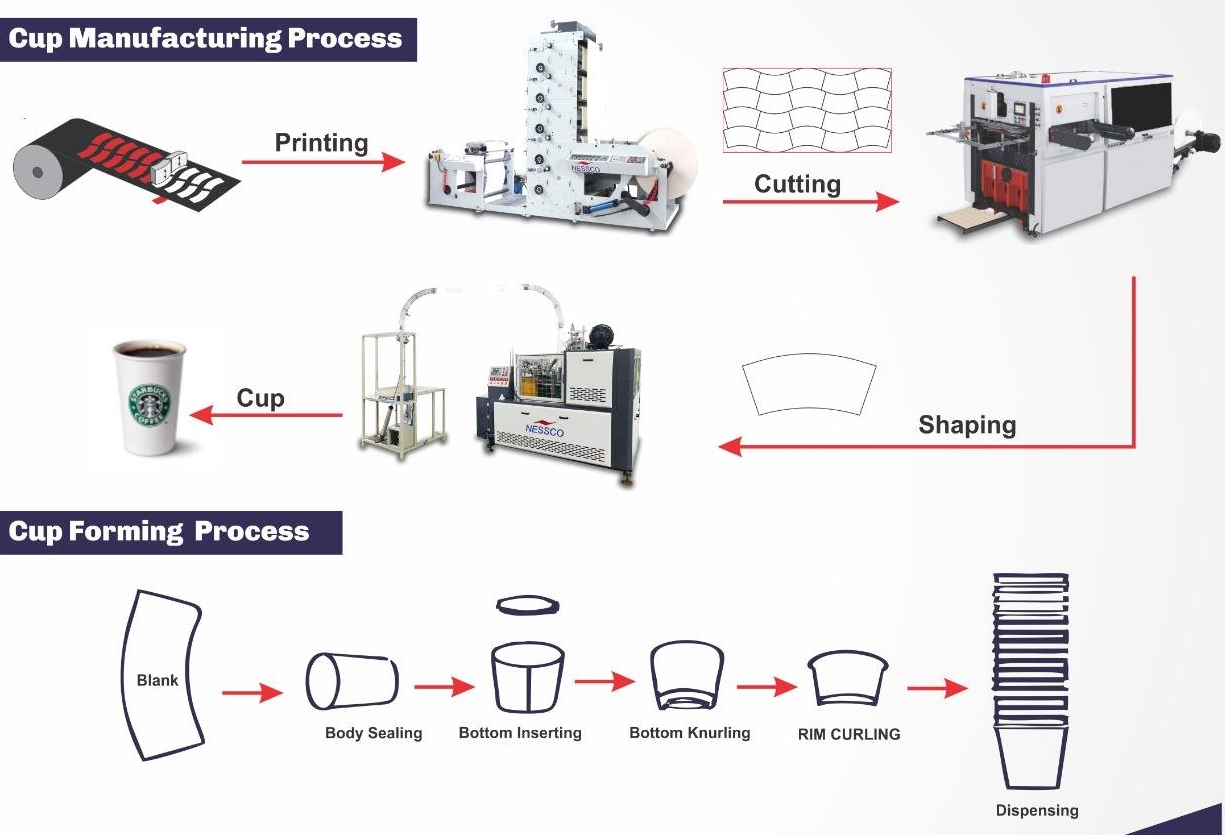

The key stages include cutting, forming, coating, and printing. First, cutting machines create cup blanks of various sizes. The blanks fit specific volumes, like 4 oz, 8 oz, or 16 oz. Next, a cup-forming machine shapes these blanks into cups. The folding and sealing process occurs under heat and pressure, forming secure bonds. After that, manufacturers apply coatings mainly for providing leak-proofing and adhering to food safety standards. You can learn more about some of the custom printed paper cups that elevate branding through effective designs and materials.

Automated machinery plays a critical role in large-scale production of paper cups. Machines can produce up to 190 cups per minute. Automation enhances efficiency, accuracy, and consistency in production. The process also involves rigorous quality control checks. These checks guarantee that the final product meets standards before packaging and distribution.

Several materials are essential for high-quality paper cup production. Common choices include SBS (Solid Bleached Sulfate), kraft paper, and bamboo. SBS is known for its brightness, making it ideal for colorful prints. Kraft paper is unbleached and offers superior strength, which makes it suited for hot beverages. Bamboo paper is eco-friendly, biodegradable, and sturdy, making it an attractive option.

Coating options include polyethylene (PE), wax, and PLA (Polylactic Acid). PE is the most popular choice for its durability and leak-proof nature. Wax offers a natural barrier, while PLA represents a bioplastic option, aligning with eco-friendly initiatives. Each coating type has its benefits and limitations in bulk procurement.

For example, PE-coated cups can withstand high temperatures, while wax coatings often have lower durability. Knowing these differences helps businesses make informed decisions about their materials.

There are three main types of paper cups: single-wall, double-wall, and ripple wall cups.

-

Single-wall cups: These are the simplest. They consist of two layers of paperboard with no insulation. They are affordable and best for cold drinks.

-

Double-wall cups: These cups have an air gap between two layers of paper, providing better insulation. They are ideal for hot beverages, as they prevent burns to the user's hands.

-

Ripple wall cups: These feature a corrugated structure. This design enhances insulation while adding an eye-catching aesthetic.

When choosing a type of cup for bulk orders, consider the beverage type. Single-wall cups are great for cold drinks, while double-wall and ripple wall cups work well with hot beverages. The type of cup significantly impacts manufacturing cost and practicality.

Below is a quick comparison of the different cup types:

| Type kopp | Layers | Isolasjon | Ideell bruk | Kostnader |

|---|---|---|---|---|

| Single-wall | 1 | Nei | Cold beverages | Lav |

| Double-wall | 2 | Ja | Hot beverages | Moderat |

| Ripple wall | 2 (corrugated) | Ja | Hot beverages | Høyere |

Understanding these options allows your business to choose suitable cups while optimizing costs. This knowledge also helps in communicating your sustainability credentials effectively.

In bulk procurement, being informed about the paper cup manufacturing process can help businesses make better decisions. You can negotiate better with suppliers, choose the right type of cups, and boost overall satisfaction with your orders.

What Are the Key Steps in the Paper Cup Manufacturing Process?

The manufacturing process of paper cups is essential for businesses engaged in bulk procurement. Understanding this process can aid in making informed purchasing decisions. Below, I will break down the critical steps involved in manufacturing these cups, from paper preparation to quality control.

Paper Preparation: Cleaning, Pulping, and Bleaching

The starting point of any paper cup is the paperboard, generally derived from food-grade sources. This paperboard comes from forests that follow sustainable practices. Initially, the paper undergoes cleaning to eliminate any impurities. Next, it is transformed into pulp. The pulping process may include both mechanical and chemical methods to further reduce the wood fibers into a usable form.

After pulping, the paperboard is bleached. This step enhances the whiteness of the paper, giving it a clean appearance for branding and design. Typical bleaching agents can include hydrogen peroxide and chlorine dioxide, ensuring food safety and compliance with regulations.

Die-Cutting and Forming: Creating Cup Shapes

Once the paper is prepared, the next phase is die-cutting and forming. This process involves cutting the cleaned and bleached paperboard into specific shapes known as "cup blanks." These blanks are tailored for different cup sizes, including common capacities like 4 oz, 8 oz, 12 oz, and 16 oz.

The cup blanks are then shaped into cups using a specialized forming machine. This involves folding and sealing the paper under heat and pressure to ensure secure bonding. The edges are often sealed to create leak-proof containers, which is crucial for businesses looking to maintain quality while serving beverages.

Application of Coatings and Printing Techniques

Now, we come to an essential part of the manufacturing process—the application of coatings and printing. To achieve durability and prevent leaks, a polyethene (PE) coating is applied to the interior of each cup. This coating is vital for food safety and serves as a barrier against liquids, ensuring that beverages do not seep through.

In addition, branding plays a significant role in paper cup manufacturing. Printing methods like offset and flexographic printing allow businesses to customize the appearance of their cups. Companies can incorporate logos and other brand identifiers, enhancing their marketing efforts. It is essential to use eco-friendly inks in this process, reflecting a company's values and commitment to sustainability.

The Role of Printing and Branding in Paper Cup Manufacturing

| Utskriftsmetode | Kvalitet | Speed | Ideell for |

|---|---|---|---|

| Offsettrykk | Høy | Slower setup; better for short runs | Detailed designs |

| Flexografisk trykk | Moderate to High | Faster setup; ideal for long runs | Large volume orders |

Methods: Offset and Flexographic Printing

Offset and flexographic printing are two prevalent methods employed in the customization of paper cups. Offset printing is known for its ability to produce high-quality images. It allows for detailed designs to be transferred onto the paper evenly. Flexographic printing also provides vibrant results and is often simpler for long runs since it requires less setup time.

Customizability and Its Significance in Bulk Orders

One of the key benefits of customizing paper cups is the range of options available. Businesses can choose colors, graphics, and sizes that align perfectly with their branding. Custom cups serve as excellent marketing tools, enhancing brand recognition during events like parties and promotions.

When procuring cups in bulk, customizability greatly influences the decision-making process. A popular beverage shop can leverage unique designs to create a memorable customer experience while retaining its brand identity.

Incorporation of Eco-Friendly Inks and Branding Considerations

Using eco-friendly inks is a growing trend in paper cup manufacturing. Many consumers are becoming more aware of their environmental impact, prompting businesses to adopt sustainable practices. Eco-friendly inks contribute to a brand’s image and appeal to eco-conscious consumers, which can boost sales.

Quality Control and Compliance in Paper Cup Production

Importance of Rigorous Testing at Each Stage

Quality control is a critical aspect of the paper cup manufacturing process. It ensures that each stage of production meets strict quality standards. At every checkpoint—cleaning, pulping, forming, and sealing—rigorous tests are conducted. This guarantees that the cups will hold liquids without leaking and will maintain their integrity under various conditions.

Ensuring Adherence to Food Safety and Environmental Standards

The production of paper cups must adhere to stringent food safety and environmental standards. This includes regulations concerning materials and coatings that come into contact with food. Compliance is crucial to foster trust with consumers and regulatory bodies alike. Businesses engaged in bulk procurement need to ensure that their suppliers meet these standards consistently.

Implications for Businesses in Bulk Purchasing Decisions

Understanding the quality control processes can significantly impact purchasing decisions for businesses. Companies that prioritize quality in their procurement strategy may find that investing in higher-quality paper cups not only enhances their customer experience but also minimizes customer complaints and returns. Reliable quality directly translates to enhanced business reputation and customer satisfaction.

By grasping the intricate process of paper cup manufacturing, businesses can optimize costs and sustainability. Whether it's selecting the right materials, ensuring quality, or understanding branding through printing techniques, knowledge is key. The manufacturing process of paper cups plays a pivotal role in the broader landscape of eco-friendly and responsible business practices.

What Factors Should Businesses Consider for Bulk Paper Cup Procurement?

When businesses look to purchase paper cups in bulk, several important factors come into play. Understanding these factors can help you make informed decisions that align with your company's costs, values, and customer expectations.

Evaluating Cost Factors in Paper Cup Procurement

| Cost Factor | Impact on Procurement |

|---|---|

| Valg av materialer | Different materials have different costs |

| Fraktkostnader | Larger orders may reduce costs |

| Customization Costs | Custom designs may add to pricing |

Cost is often the primary concern when purchasing paper cups in bulk. Here are some key areas to consider:

Material Choices and Their Impact on Overall Cost

The choice of materials significantly impacts the cost of paper cup production. The main material used is food-grade paperboard, typically made from renewable resources. It is essential to compare various types of paperboard, such as SBS (Solid Bleached Sulfate), Kraft, and bamboo. Each type has different cost implications:

- SBS: Known for its excellent printability and smooth surface, it usually comes with a higher price tag.

- Kraft: This is often more economical but may sacrifice some print quality.

- Bambus: An innovative option, bamboo paperboard can be costlier to source but appeals to eco-conscious customers.

Additionally, most cups require a 5% polyethylene (PE) coating to ensure leak resistance. This coating adds extra costs, so understanding how each material affects your final price is vital.

Economies of Scale: Cost-Efficiency in Bulk Orders

Purchasing paper cups in bulk often leads to cost reductions due to economies of scale. When you order larger quantities, suppliers can reduce the costs of raw materials, production, and shipping. This savings can sometimes be substantial:

- Kvantumsrabatter: Most suppliers offer price breaks based on quantity. For example, prices might drop significantly for orders over 10,000 cups.

- Reduced Shipping Costs: Larger orders often justify less frequent shipments, reducing overall transportation costs.

Long-Term Savings Through Sustainable Practices

Investing in sustainable practices can lead to substantial long-term savings. While eco-friendly materials like biodegradable PE and recycled content may have higher initial costs, they can enhance your brand's image and attract more customers.

Research from the National Association for Paper Traders shows that companies that adopt green policies can see up to a 10% increase in customer loyalty and overall sales. This loyalty translates into repeat business, thus saving money in the long run.

Supplier Selection and Comparison

Choosing the right supplier is crucial when purchasing paper cups in bulk. Here’s how to navigate this important step:

Identifying Reliable Suppliers for Paper Cups

Start with a list of potential suppliers who specialize in bulk orders. A reliable supplier usually has a track record of on-time deliveries and consistent quality.

- Research: Look at online reviews and testimonials from previous clients.

- Contact: Direct communication can help gauge their customer service and responsiveness.

Assessing Suppliers Based on Quality Assurance and Lead Time

Quality assurance and lead times are essential factors in supplier evaluation. You’ll want to ask potential suppliers:

- What quality control measures do you have in place?

- What is your average lead time for orders?

- Can you provide references from other businesses that ordered similar quantities?

It's best to select suppliers who can offer both great quality and reasonable lead times, ensuring you receive your cups when needed without compromising quality.

Case Studies of Successful Supplier Relationships

Consider reviewing case studies of successful supplier partnerships in your industry. For instance, a coffee chain may have a long-term relationship with a paper cup supplier that consistently meets its supply and quality demands while adhering to sustainable practices. Such case studies can provide insights into what works and what doesn’t.

Adopting Eco-Friendly Practices in Paper Cup Procurement

Today's customers are more eco-conscious than ever, making sustainability a vital consideration in bulk paper cup procurement.

| Eco-Friendly Practice | Fordel |

|---|---|

| Biodegradable Materials | Attracts eco-conscious consumers |

| Recycled Materials | Reduces landfill waste and promotes a circular economy |

Transition to Biodegradable and Sustainable Materials

Transitioning to biodegradable materials—such as PLA (Polylactic Acid) coatings—can enhance your brand’s image. These materials break down more easily in the environment, aligning with eco-friendly initiatives:

- Benefits: Using biodegradable materials can lead to an increase in consumer trust and loyalty.

- Challenges: These materials may have higher upfront costs.

Importance of Sustainability to Consumer Perception and Branding

A strong commitment to sustainability matters to consumers. A survey by Mintel indicated that 72% of consumers are willing to pay more for environmentally friendly products. Thus, adopting eco-friendly practices can provide a competitive edge in the market.

Case for Recycled Materials and Their Market Implications

Choosing recycled materials holds a significant opportunity for businesses. Products made from recycled paper promote a circular economy and reduce landfill waste. Moreover, they highlight your commitment to sustainability, which can enhance your brand's reputation.

Evaluating how recycled materials appeal to your target market can be beneficial. For instance, if your target audience values sustainability, opting for 100% recycled paper cups can solidify brand loyalty.

To truly capture the benefits of bulk paper cup procurement, businesses must weigh various factors, from cost evaluations to eco-friendly practices. A smart approach to supplier sourcing and material selection will help devise a procurement strategy that serves both business interests and customer expectations efficiently.

FAQs about Paper Cup Manufacturing Process for Bulk Procurement:

What is the first step in the paper cup manufacturing process?

The first step in the paper cup manufacturing process is choosing the right materials, which involves using food-grade paperboard sourced from sustainably managed forests.

How are paper cups formed after the paper is prepared?

After paper preparation, the paper cups are formed by die-cutting the paperboard into cup blanks, which are then shaped into cups using specialized machines that fold and seal them under heat and pressure.

What materials are commonly used to coat paper cups?

Common coating materials used in paper cups include polyethylene (PE) for its durability, wax for natural barriers, and PLA (Polylactic Acid) as a biodegradable option.

What are the main types of paper cups for bulk orders?

The main types of paper cups are single-wall cups for cold drinks, double-wall cups for better insulation with hot beverages, and ripple wall cups that offer both insulation and a unique aesthetic.

Why is quality control crucial in paper cup production?

Quality control ensures that each stage of paper cup production meets strict standards, guaranteeing that the cups hold liquids without leaking and comply with food safety and environmental regulations.

Understanding paper cup manufacturing is key for bulk procurement success. We explored the crucial stages: selecting materials, cutting, forming, coating, and printing. Each material, like SBS or PLA, impacts costs and sustainability. Whether you need single-wall or ripple cups, match the type to its use. Also, ensure quality control for safe, eco-friendly cups. Always choose reliable suppliers for bulk orders. Thoughtful decisions on materials and suppliers lead to cost savings and eco-awareness. This knowledge helps businesses make informed choices in purchasing paper cups at scale.