What Are the Different Types of Paper Cup Materials and Their Durability?

When it comes to food service, understanding the types of paper cup materials and their durability is crucial. Selecting the right paper cup can make a significant difference in performance, safety, and customer satisfaction. Let’s explore the most common types of paper cup materials and their unique properties.

Poly-coated Paper Cups

Poly-coated paper cups are essential in the hot beverage industry. These cups have a thin coating of polyethylene (PE) on the inside. This protective layer shields the paper from moisture, preventing leaks. When serving hot beverages like coffee or tea, these cups excel due to their ability to withstand elevated temperatures. If you want to enhance your branding with high-quality options, consider exploring custom printed paper cups that can elevate your brand image.

Durability Against Heat: Poly-coated paper cups can typically handle temperatures up to 200°F (93°C) without deforming. They maintain their structure even as the drink cools down. However, over time, excessive heat can weaken the cup's integrity.

Comparison with Other Materials: Compared to wax-coated cups or bare paper cups, poly-coated options offer far superior heat resistance. Wax-coated cups might be excellent for cold drinks but fall short at higher temperatures since the wax can melt.

Wax-coated Paper Cups

Wax-coated paper cups follow a different approach. They are ideal for cold beverages, like iced coffee or soft drinks. The wax coating keeps the cups from absorbing moisture, maintaining their strength and shape.

Cost-effectiveness and Limitations: Wax-coated cups tend to be more affordable than other types. Their cost-effectiveness makes them popular in bustling food service environments where price matters. However, they are not suitable for hot drinks as the wax can melt, compromising integrity.

Impact on Condensation and Thermal Insulation: These cups handle condensation well, making them perfect for iced beverages. They help prevent moisture buildup on the outside of the cup, providing a better grip for customers. Still, they lack any significant thermal insulation. If customers need optimal heat retention, poly-coated cups would be more effective.

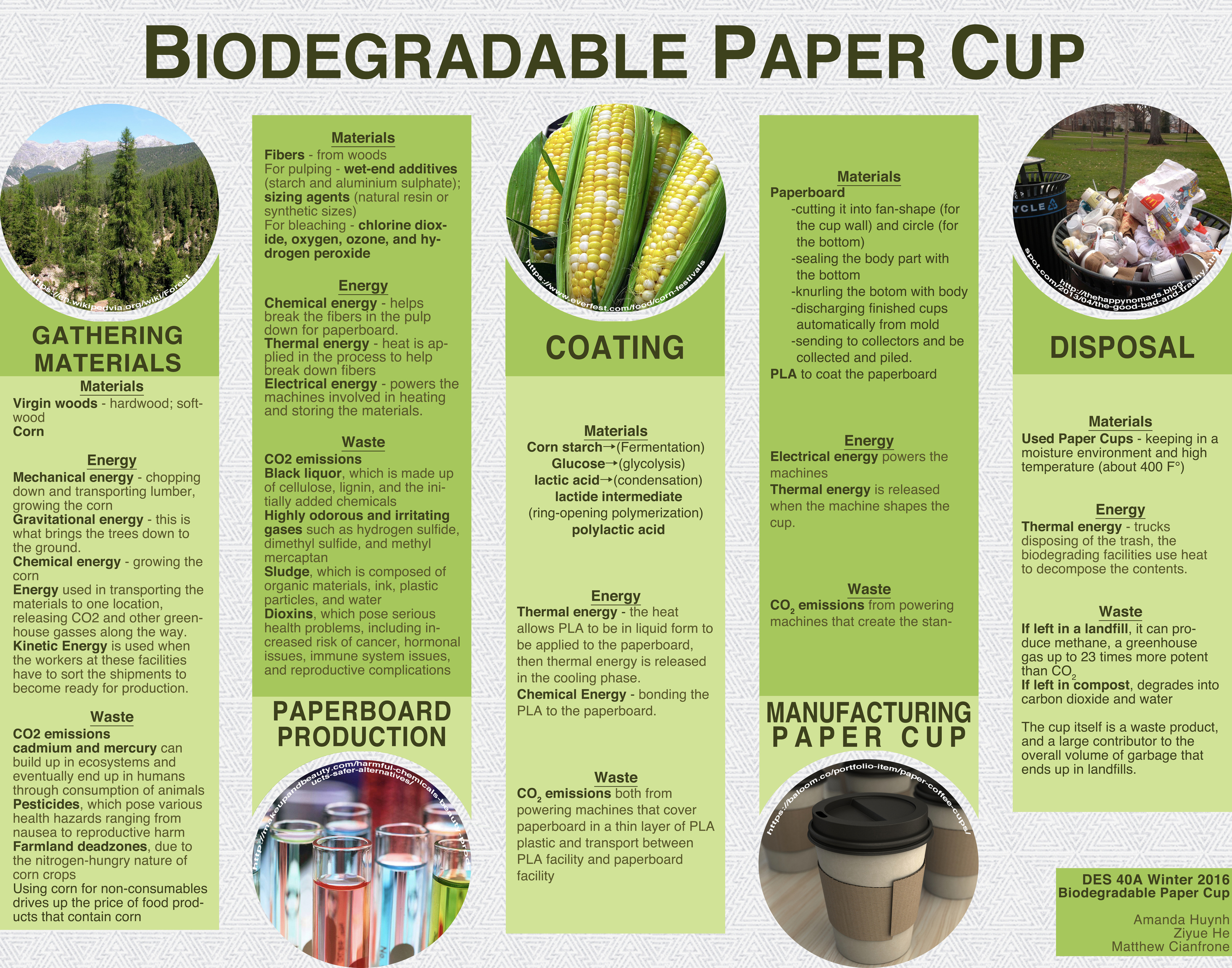

Biologisk nedbrytbare papirkopper

A hot trend in the food service sector is biodegradable paper cups. These cups take sustainability to the next level. Biodegradable options include materials like polylactic acid (PLA), bagasse, and bamboo fiber. If you're interested in the environmental benefits and decomposition rates, check out detailed insights about biodegradable materials in food service.

Materialsammensetning:

- PLA: Derived from renewable resources, such as corn starch, PLA cups offer an eco-friendlier choice than petroleum-based plastics.

- Bagasse: Made from sugarcane residue, bagasse cups are strong and robust, suitable for both hot and cold contents.

- Bamboo Fiber: This quickly-growing material forms strong cups with minimal resource use, making it a great choice for eco-minded consumers.

Environmental Benefits and Decomposition Rate: Biodegradable cups decompose faster than traditional paper cups. Unlike plastic, they break down naturally, reducing landfill waste and pollution. PLA cups, for instance, typically decompose in about 90-180 days under composting conditions.

Suitability for Food Service Applications and Consumer Preferences: Eco-conscious consumers prefer biodegradable options, as they avoid harmful chemicals like styrene and are non-toxic. Their appeal extends to businesses aiming to improve their sustainability footprint.

What Materials are Used in the Making of Paper Cups for Food Service?

Various materials go into making paper cups for food service. Common choices include poly-coated, wax-coated, and biodegradable materials like PLA and bagasse. Food-grade paper boards ensured safety and reliability.

How Do Different Coatings Affect the Durability and Safety of Paper Cups?

The coatings on paper cups play a significant role in durability and safety. Polyethylene and wax coatings prevent moisture absorption and leaks. Plant-based coatings can sometimes offer compostability and appeal to safety-conscious consumers.

A blend of practical performance and safety features makes these cups staples in food service. Customers tend to favor brands emphasizing safety, as evidenced by research where 78% prioritize brands that focus on sustainability over mere profits.

In summary, understanding paper cup material types and their respective durability is essential for any food service business. Each paper cup type has its unique advantages and potential limitations. By choosing the right materials and coatings, businesses can offer both excellent service and safety, appealing to consumers’ growing environmental concerns.

How Do Material Coatings Affect Paper Cup Durability in Food Service?

When choosing paper cups for food service, the types of coatings used are crucial for durability and safety. The choice of material coatings can impact everything from leaks to thermal resistance, directly affecting your customers' satisfaction. Below, we dive into the details of various coatings, focusing on plant-based coatings, polyethylene and wax coatings, and the usage of food-safe ink.

Plant-based Coatings

Importance for safety-conscious consumers

Plant-based coatings are gaining traction among businesses aiming to satisfy safety-conscious consumers. Around 50% of customers consider food safety a priority when selecting products. With plant-based coatings derived from renewable resources like cornstarch, brands can appeal to eco-aware clients who seek sustainable choices for their food service needs.

Benefits of compostability and environmental impact

Plant-based coatings are compostable, which is a significant advantage for environmentally responsible businesses. Unlike traditional coatings, plant-based options decompose more rapidly. By reducing landfill waste, they help lower the carbon footprint associated with food service operations. This shift towards sustainable practices is important, as 78% of customers prefer brands focused on both safety and sustainability.

Polyethylene (PE) and Wax Coatings

Role in preventing leaks and moisture absorption

Polyethylene (PE) and wax coatings are primarily designed to prevent leaks and moisture absorption, which are vital traits for paper cups used in food service. PE coatings can create a reliable barrier against water, maintaining the cup’s structural integrity. In contrast, wax coatings are moisture-resistant yet not ideal for hot beverages. Their application is effective in cold drink scenarios, ensuring durability while keeping costs lower.

Comparison of price versus performance

While both coatings serve essential functions, polyethylene coatings generally provide better overall performance for hot beverages compared to wax coatings. However, the price difference can impact budget-conscious businesses. Overall, while poly cups may have a higher upfront cost, their reliability can lead to decreased waste and, ultimately, cost-effectiveness in the long run.

| Coating Type | Best Use | Kostnader | Holdbarhet |

|---|---|---|---|

| Polyethylene (PE) | Hot beverages | Moderat | Høy |

| Wax | Cold beverages | Lav | Moderat |

Food-safe Ink Usage

Potential risks of UV cured inks

When printing on paper cups, it's vital to consider the inks used. UV cured inks, while common in digital printing, can pose risks if not properly cured. Improper curing may lead to chemical migration into food, creating potential safety hazards. This risk emphasizes the need for careful selection of ink types.

Benefits of using non-toxic and water-based inks

In stark contrast, food-safe inks are typically non-toxic and water-based, making them a far safer choice for paper cup printing. Since they are free from harmful chemicals, these inks do not leach into food or drinks, thus ensuring consumer safety. This aspect can greatly enhance brand trust, especially among consumers who are vigilant about health risks.

| Ink Type | Safety Level | Miljøpåvirkning |

|---|---|---|

| UV Cured Inks | Risky | Moderat |

| Non-toxic Water-based | Safe | Lav |

What are the safest coatings for paper cups in food service?

The safest coatings for paper cups in food service are plant-based and food-safe water-based inks. Plant-based coatings provide a compostable solution that appeals to environmentally conscious consumers. Meanwhile, non-toxic inks ensure no harmful substances leach into food or drinks, significantly reducing potential health risks.

How do coatings impact the thermal resistance and durability of paper cups?

Coatings play a crucial role in the thermal resistance and overall durability of paper cups. For hot liquids, polyethylene-coated cups perform reliably due to their ability to withstand heat without leaking. Double-wall designs further enhance insulation, making them suitable for serving hot beverages. On the other hand, wax coatings are more effective with cold drinks, as they can resist moisture but cannot handle high temperatures.

| Coating Type | Thermal Resistance | Durability for Foods |

|---|---|---|

| Polyethylene (PE) | (High) | Excellent |

| Wax | (Low for hot drinks) | Moderate for cold drinks |

By understanding these coatings and their implications, businesses can choose the best paper cup options to balance safety, durability, and environmental sustainability.

What Factors Should Be Considered When Choosing Paper Cups for Food Service?

When you are in charge of choosing paper cups for food service, several factors come into play. Each aspect affects not only customer satisfaction but also your brand's reputation and the environment. Let's dive into the critical considerations: safety and food-grade certifications, environmental impact, and cost and customization options.

Safety and Food-grade Certifications

Safety is paramount. You want to ensure that the paper cups you choose are safe for food service. For example, quality paper cups should use food-grade paper boards. This type of board prevents chemical leaching, which can compromise food safety. Remember that 50% of customers consider food safety when purchasing food products. Thus, it’s crucial to make informed choices about your suppliers.

In terms of certifications, look for suppliers that hold recognized standards, such as ISO and food safety certifications. Certifications serve as proof that the materials meet safety requirements. For example, food-grade inks are crucial to avoid contamination. These inks should be non-toxic and water-based, ensuring that no harmful substances seep into your beverages. Historical recalls, like those involving MacDonald's or Nestlé, highlight the importance of ensuring safety measures are in place.

Here are some essential certifications that food service cups should have:

- ISO 22000: Food Safety Management

- FDA Approval: Ensures compliance with U.S. food safety regulations

- FSC Certification: Assures the paper source is sustainable and eco-friendly

Environmental Impact and Sustainability

As a consumer, today's diners are increasingly aware of environmental impacts. They prefer miljøvennlige alternativer. This calls for opting for recycled and biodegradable materials when choosing paper cups. Notably, cups made from sustainable materials can include PLA (polymelkesyre) from cornstarch or bagasse from sugarcane waste. These materials are compostable and reduce landfill waste.

When choosing suppliers, understand their commitment to sustainability. Are they involved in environmental programs? Suppliers who participate in carbon offset initiatives contribute to reducing their carbon footprint and help prevent climate change. Remember that consumers tend to favor brands that prioritize sustainability. In fact, 78% of customers prefer companies focused on safety and sustainability over those solely interested in profits.

Cost and Customization Options

As you balance the quality of paper cups with cost-effectiveness, keep in mind that you can achieve quality while being budget-friendly. Opt for suppliers offering competitive pricing, particularly for bulk orders. Investing slightly more into higher-quality cups can pay off in customer satisfaction and reduced waste.

Customization options also play a crucial role in your choice. Having the ability to print your logo or a theme on cups can enhance your brand visibility and marketing efforts. Quality printing can provide a professional look, reinforcing your brand's commitment to quality and safety.

To help you evaluate the overall cost and value of your options, here’s a brief list of pricing considerations:

- Compare costs for bulk orders across multiple suppliers.

- Assess the durability of the cups against the price to gauge overall value.

- Consider potential waste and how higher-quality cups can save costs in the long run.

Summary of Key Considerations

In summary, the right paper cup for your food service business should fulfill safety requirements, minimize environmental impact, and offer customization without breaking the budget.

Takeaways include:

- Prioritize food-grade certifications to ensure safety.

- Choose sustainable materials to appeal to eco-conscious consumers.

- Find a balance between quality and cost while maximizing customization options.

By considering each of these factors, you can make a more informed decision that benefits both your brand and your customers.

FAQs about Paper Cup Material Types and Durability for Food Service

What materials are used in the making of paper cups for food service?

The materials used in making paper cups for food service include poly-coated, wax-coated, and biodegradable options like PLA and bagasse, all supported by food-grade paper boards for safety and reliability.

How do different coatings affect the durability and safety of paper cups?

Different coatings on paper cups influence durability and safety by using polyethylene or wax to prevent moisture absorption and leaks, with plant-based coatings offering compostability for environmentally conscious consumers.

What are the safest coatings for paper cups in food service?

The safest coatings for paper cups in food service are plant-based coatings and food-safe water-based inks, as they provide compostable solutions and reduce potential health risks by ensuring no harmful chemicals leach into food or drinks.

How do coatings impact the thermal resistance and durability of paper cups?

Coatings impact the thermal resistance and durability by offering polyethylene-coated cups excellent heat resistance for hot beverages, while wax coatings are best for cold drinks due to moisture resistance but poor heat handling.

What factors should be considered when choosing paper cups for food service?

Factors to consider when choosing paper cups for food service include ensuring safety with food-grade certifications, minimizing environmental impact with biodegradable materials, and finding a balance between quality and cost with customization options.

We've explored the materials and coatings that impact paper cup durability. Poly-coated cups hold up well against heat, while wax-coated ones excel with cold drinks. Biodegradable options shine for the environment. Coatings like plant-based shine for safety and compostability, while PE and wax prevent leaks. Safety certifications and environmental impact are key when choosing paper cups. Always balance cost with quality and eco-friendliness. Remember, a thoughtful choice affects customer safety and the planet.