How Are Paper Cups Sourced and Manufactured for Distribution?

Sourcing sustainable materials, such as biodegradable paper, is very important for the paper cup supply chain. Environmentally friendly practices attract eco-conscious consumers. The right materials can improve customer loyalty while reducing the impact on our planet. For more insights on different types of paper cup materials, check out this article on exploring paper cup material types and durability.

Identifying High-Quality Materials for Paper Cup Production

When producing paper cups, the quality of materials is crucial. High-quality materials ensure cups are durable and effective. Common materials used include virgin or recycled paper and coatings. Coatings can be made from polyethylene (PE) or polylactic acid (PLA) to provide water resistance. These choices also support sustainability.

Key Materials in Paper Cup Production:

- Virgin Paper: This is fresh tree-derived paper, offering great durability.

- Recyklovaný papír: This reduces waste, providing an eco-friendly option.

- Povlak PLA: A biodegradable alternative to traditional plastic.

- Bagasse: Making cups from sugarcane pulp supports sustainable practices.

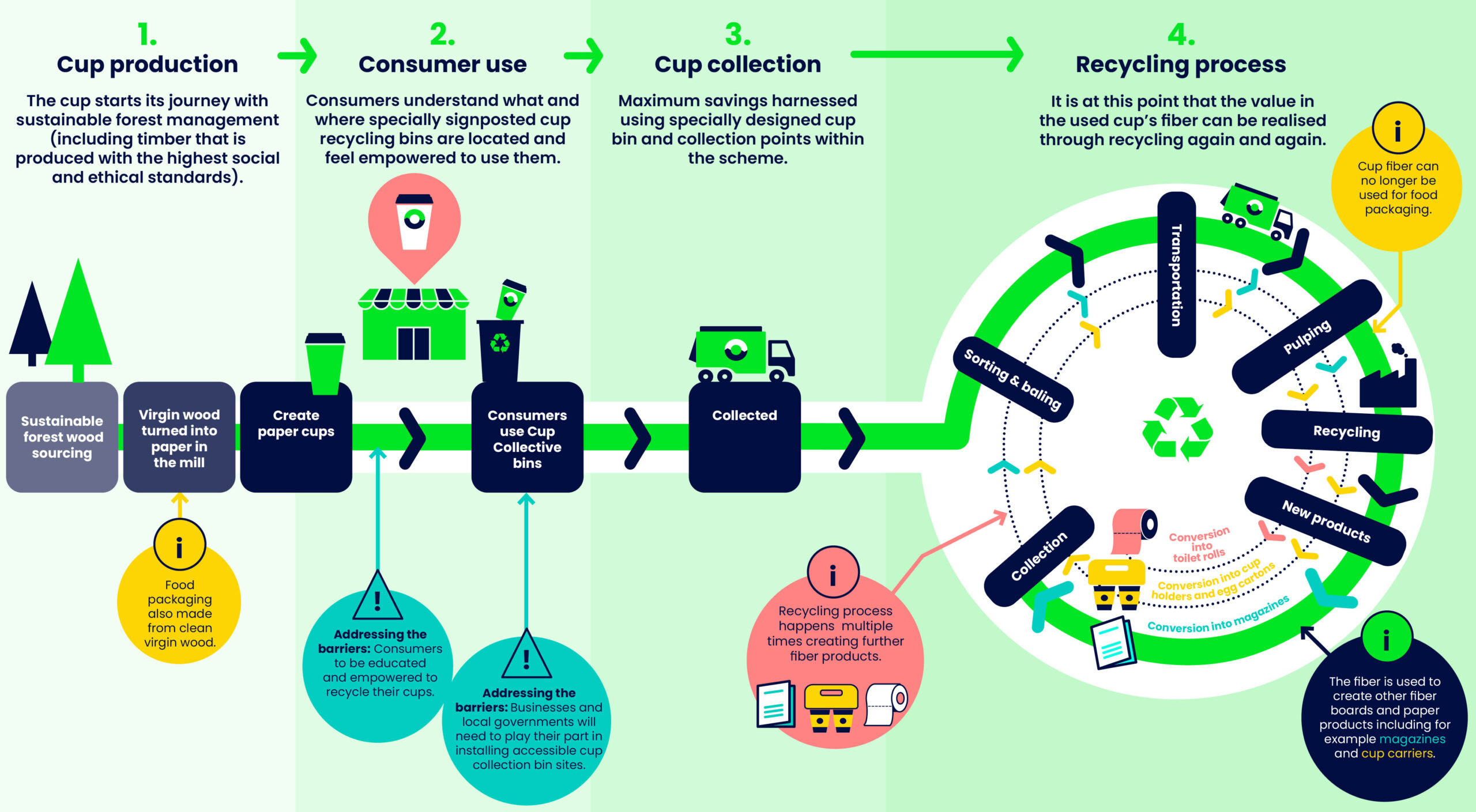

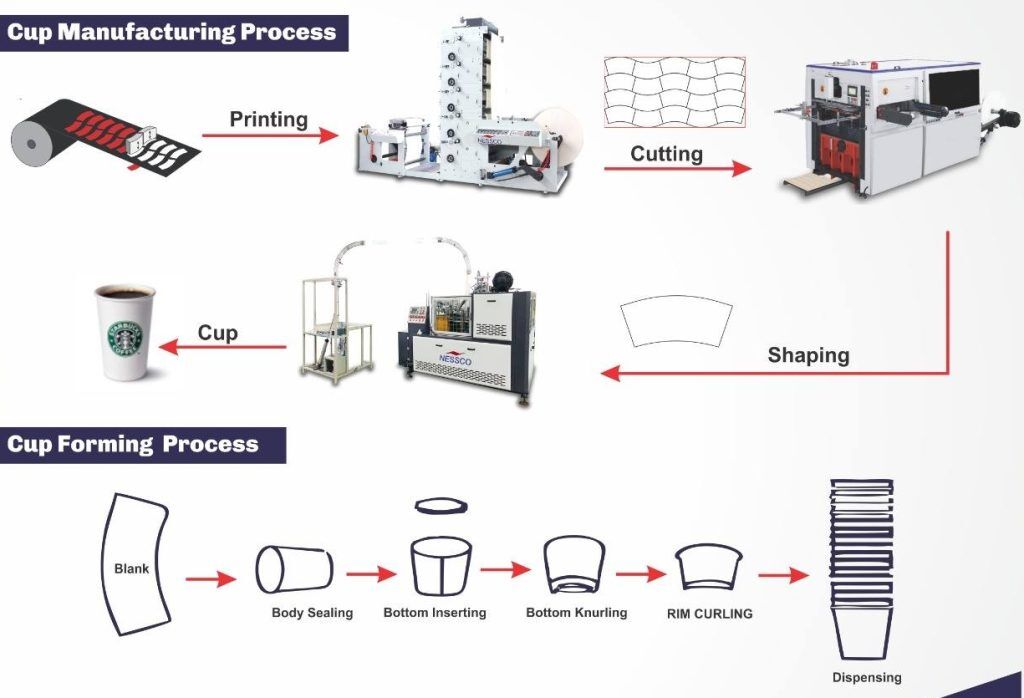

Overview of the Paper Cup Manufacturing Process

The paper cup manufacturing process involves several stages. Each stage plays an important role in ensuring the final product meets quality and sustainability standards.

- Příprava materiálu: The first step is sourcing high-quality paper. The paper is checked for potency and sustainability.

- Printing & Coating: Next, designs are printed on the paper. After printing, cups receive a coating to make them waterproof. This step is often where both PE and PLA are used.

- Forming: In this stage, the coated paper is cut and folded into cup shapes. Different machinery can make various cup designs, including single-wall and double-wall options.

- Quality Check: This is one of the most critical stages. Cups are checked for durability, insulation, and leaks. Each cup must pass strict tests to ensure they meet industry standards.

- Balení: Finally, the cups are packed for shipping. Efficient loading strategies are often utilized to maximize space and reduce shipping costs.

Fact: The compostable plastics market, covering biodegradable materials, was valued at $1.43 billion in 2020 and is projected to grow to $3.40 billion by 2027 at a CAGR of 13.2%.

Key Certifications for Sustainable Sourcing

When it comes to sourcing materials for paper cups, certifications matter. Certifications indicate whether materials meet sustainability and safety standards. Key certifications include:

- Forest Stewardship Council (FSC): This ensures the wood and paper used come from responsibly managed forests.

- Biodegradable Products Institute (BPI): BPI certification guarantees that compostable materials meet specific requirements.

- Cradle to Cradle Certification: This evaluates materials for safety and sustainability across their entire lifecycle.

Choosing suppliers with these certifications helps ensure you use high-quality, sustainable materials.

Challenges in Sourcing Sustainable Materials and Potential Solutions

Sourcing sustainable materials can be challenging. Some common issues include limited availability, higher costs, and fluctuating prices.

Challenges:

- Availability: Sustainable materials can be hard to find.

- Higher Costs: Producing eco-friendly cups often costs more than traditional options.

- Price Fluctuations: Prices can change due to market demands or changes in supply.

Potential Solutions:

- Establish Strong Relationships with Suppliers: By doing this, you can ensure reliable sources and potentially better pricing.

- Support Local Suppliers: Local sourcing reduces transportation costs and contributes to local economies. Learn more about minimum order quantities in this helpful piece on paper cup minimum order quantities for wholesale buyers.

- Invest in Efficient Inventory Management: Utilize systems to track stock and predict demand, helping avoid shortages or excess.

Impact of Grammage (GSM) on Quality and Durability of Paper Cups

Grammage, measured in grams per square meter (GSM), is essential in paper cup production. Higher GSM generally means thicker, more durable cups. For example, a 250 GSM cup feels sturdier than a 200 GSM cup.

| GSM | Application |

|---|---|

| 200 GSM | Often used for lighter drinks or cold beverages. |

| 250 GSM | Ideal for hot beverages or heavy-duty usage. |

Choosing the right GSM affects cup performance and user experience.

Role of Biodegradable and Compostable Materials in Manufacturing

Using biodegradable and compostable materials is vital for reducing environmental impact. Cups made from these materials break down more quickly than traditional plastics. Examples include:

- Kelímky z PLA: These can compost in commercial facilities, providing an eco-friendly option for consumers.

- Bagasse cups: Made from sugarcane fiber, these are both renewable and biodegradable.

Investing in sustainable materials increases brand loyalty and reduces the carbon footprint.

Information on Compostability:

- To be considered compostable, a product must break down into non-toxic components in a specific time frame. Generally, this means within 90-180 days in a suitable commercial composting facility.

By understanding how paper cups are sourced and manufactured, distributors can improve their supply chain management. They can also meet growing consumer demand for sustainable products while maintaining product quality. This process can also enhance relationships with customers and strengthen brand identity.

FAQs about Paper Cup Supply Chain Management for Distributors

How are paper cups sourced and manufactured for distribution?

To source and manufacture paper cups for distribution, sustainable materials like biodegradable paper are prioritized, with eco-friendly practices enriching customer loyalty and reducing environmental impact.

What are the key materials used in paper cup production?

The key materials in paper cup production include virgin paper for durability, recycled paper for eco-friendliness, PLA coating as a biodegradable option, and bagasse sourced from sugarcane pulp for sustainable manufacturing.

What does the paper cup manufacturing process involve?

The paper cup manufacturing process involves stages like material preparation, printing and coating for waterproofing, forming paper into cups, quality checking for durability and leak prevention, and efficient packaging.

How can distributors ensure they are sourcing sustainable materials?

To source sustainable materials, distributors should look for certifications like the Forest Stewardship Council (FSC), Biodegradable Products Institute (BPI), and Cradle to Cradle Certification to guarantee environmental and safety standards.

What are the challenges in sourcing sustainable materials and their solutions?

The challenges in sourcing sustainable materials include limited availability, higher costs, and price fluctuations, which can be managed by building strong supplier relationships, supporting local suppliers, and investing in efficient inventory management.

Understanding the paper cup supply chain is key to sustainable and cost-efficient practices. We explored how sourcing eco-friendly materials, like biodegradable paper, and securing key certifications can ensure quality. Efficient logistics, such as route optimization and smart inventory management, keep distribution smooth. Finally, choosing the right suppliers and design options helps in reducing costs while upholding sustainability standards. By focusing on these strategies, we can make informed choices that both benefit the environment and boost business efficiency.